AT3-133R 3.5MM or 1/8th” TRS Jack Connector Rhodium Plated Copper

£50.00

6 in stock

Description

These are some of the nicest 3.5mm TRS connectors on the market.

The contacts are machined from Tellurium Copper, directly plated in Rhodium.

Concept

Shell between body isolate by insulator material. Depends on the method of processing, it can choose to make the shell be a conductor.

The conductor is made from high-purity tellurium copper without nickel base.

By using highest quality of design techniques and material to provide customer who has “Hi-End” requirement.

Description

The center pin is fixed to the POM insulator by assemble function

Ring and the end sleeve is separate by POM, then assemble with center pin.

There’ s a hole between the contact pin and body structure.

To put the fillers into the gap of the body from the hole.

Use the POM latch through to fix the body.

The body and the shell locked by screwing.

POM sleeve is fixed with end of shell by using screw.

Note:

This product is include: screw for cable 3 mm*1pcs and 4 mm*1pcs.

Due to the 3.5mm plug size is small, the over soldering time will cause the insulator damage or swelling. Please process solder each channel based on recommend soldering temperature and condition.

This plug unable to contact with the adaptor which the ground is contact the sleeve conductor by shell.

Assembly:

1. We recommend to peel off the cable jacket and per conductor wire insulation.

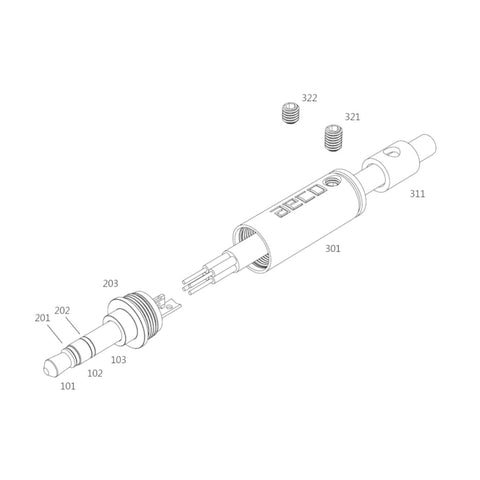

2.Depends on cable size to decide whether use sleeve (ID 4.5mm) [311], or without sleeve (ID6.5MM) [301].Then through into cable.

3.Contact the cable with per channel by soldering.

4.Lock the shell and body [203],

5. Please lock the cable and shell with a screw M3x4mm [321] or M3x3mm [322].

Finish:

AT3-1331R

Contact pin : Rhodium plating (no nickel base).

Body : Rhodium plating (no nickel base).

Insulator : None.

Head lock : None.

Shell : Satin Nickel + Topcoat.

Sleeve : None.

Screw : None.

Electrical Characteristics:

Contact resistance < 1.0 mOhm

Dimension:

Biggest OD : 8.90 mm

Total Length : 42.3mm

Cable hole :

Sleeve contained in shell is 4.5mm.

Sleeve not contained in shell is 6.5mm.

Package:

Vacuum Bag(1Pcs)

place in the sponge then pack in the vacuum bag.

Recommend soldering temperature:

Contact pin (Tip)

Temperature Soldering Iron, please keep 340 °C within 4~7 second

Temperature Soldering Iron, please keep 360 °C within 3~6 second

Temperature Soldering Iron, please keep 380 °C within 2~5 second

Temperature Soldering Iron, please keep 400 °C within 1~4 second

Body (Ring)

Temperature Soldering Iron, please keep 340 °C within 9~12 second

Temperature Soldering Iron, please keep 360 °C within 6~9 second

Temperature Soldering Iron, please keep 380 °C within 5~8 second

Temperature Soldering Iron, please keep 400 °C within 2~5 second

Body (Sleeve)

Temperature Soldering Iron, please keep 340 °C within 6~9 second

Temperature Soldering Iron, please keep 360 °C within 5~8 second

Temperature Soldering Iron, please keep 380 °C within 3~6 second

Temperature Soldering Iron, please keep 400 °C within 2~5 second

Product production process comply with RoHS.

Product made new TW patent No. M581795.

Related products

-

Banana Plug Tellurium Copper Silver Plated aeco ABP-1111S, Set Of 4

0 out of 5Add to basket -

Silver Plated Tellurium Copper aeco Chassis RCA Sockets 2 pcs ARJ-4043S,

0 out of 5Add to basket -

New AECO XLR Tellurium Copper Gold Plated Connectors AMI-1060G – 1 Pair (1x female & 1 x male)

0 out of 5Add to basket -

Pure Silver RCA Connector aeco ARP-4055 1 x set of 4

0 out of 5Add to basket

Reviews

There are no reviews yet.