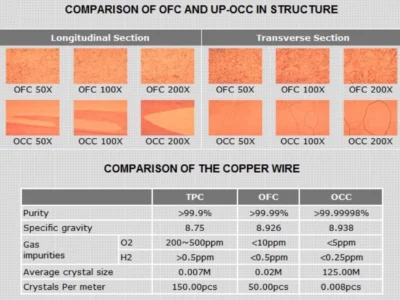

As for conducting materials, normal, high purity copper has about 1500 grains in each foot (5000/m). The signal must cross the junctions between these grains 1500 times in order to travel through one foot of cable. These grain boundaries cause the same type of irritating distortion as current crossing from strand to strand.

The first grade above normal high purity copper is called Oxygen-Free High-Conductivity (OFHC) copper. In fact, this copper is not Oxygen-Free, it should more properly be called Oxygen-Reduced. OFHC is cast and drawn in a way that minimizes the oxygen content in the copper: approximately 40 PPM (parts per million) for OFHC compared to 235 PPM for normal copper. This drastically reduces the formation of copper oxides within the copper, substantially reducing the distortion caused by the grain boundaries. Additional improvement can be attributed to OFHC copper having longer grains (about 400 per foot), further reducing distortion. The sound of an OFHC copper cable is smoother, cleaner, and more dynamic than the same design made with standard high purity copper.

Not all OFHC is the same. If the poorest copper were given a value of one, and the best was a ten, then OFHC ranges from two to four-it is actually a range rather than a single performance level.

The next higher grade is an elongated grain copper sometimes called “linear-crystal” (LC-OFC) or “mono- crystal”. These coppers have been carefully drawn in a process that results in only about 70 grains per foot. Cables using LC-OFC have an obvious audible advantage over cables using the same designs with OFHC.

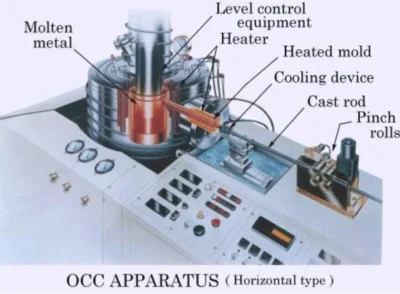

In 1986 the Ohno Continuous Casting (OCC) process was introduced. The world patent “UP-OCC” (Ultra Pure Copper by Ohno Continuous Casting Process) was developed by professor Ohno of Chiba Institute of Technology in Japan. This technology has been applied to the manufacturing of single crystallized copper with the process of heated mold continuous casting. The resulting product are small rods of OCC pure copper, from which the wire can be drawn and which can have Copper grains of over 700 ft length.

Because of its characteristics of single crystal, unidirectional, free of impurity, flexible fatigue-resistance, corrosive-resistance, low electric resistance, none-crystal boundaries, rapid transmissibility, perfect in structure, and easy to process, all make it an ideal material for making rapid transmission lines. From inner hook up wires to interconnect cables, they can be widely applied to Hi-Tech products such as Hi-Fi stereo system, high resolution TV.

A couple of years later the “nines” race began. This refers to how many times the number “9” can be repeated when specifying a metal’s purity. The prime contaminants in very high purity (99.997% pure, four nines) copper are silver, iron and sulfur, along with smaller amounts of antimony, aluminum and arsenic. The purity of OCC Copper can reach up to 99.9999% and even higher

But with OFHC and OCC, the nomenclature “six nines” or “eight nines” has almost no meaning. All else being equal, higher purity is a straight forward benefit. However, grain structure, softness and surface finish can each make more difference than a “nine” or two. Then there is the matter of measurable purity. Due to contamination caused by the measuring process, there is a serious question as to whether any metal can be verified as having greater than six nines purity. Also, since “nines” became a selling point, some quite absurd and dubious claims have been made.