AECO ASP-1931R High-Purity Copper Spade Connectors – Rhodium Plated (Set of 4)

£90.00

3 in stock

Description

Concept

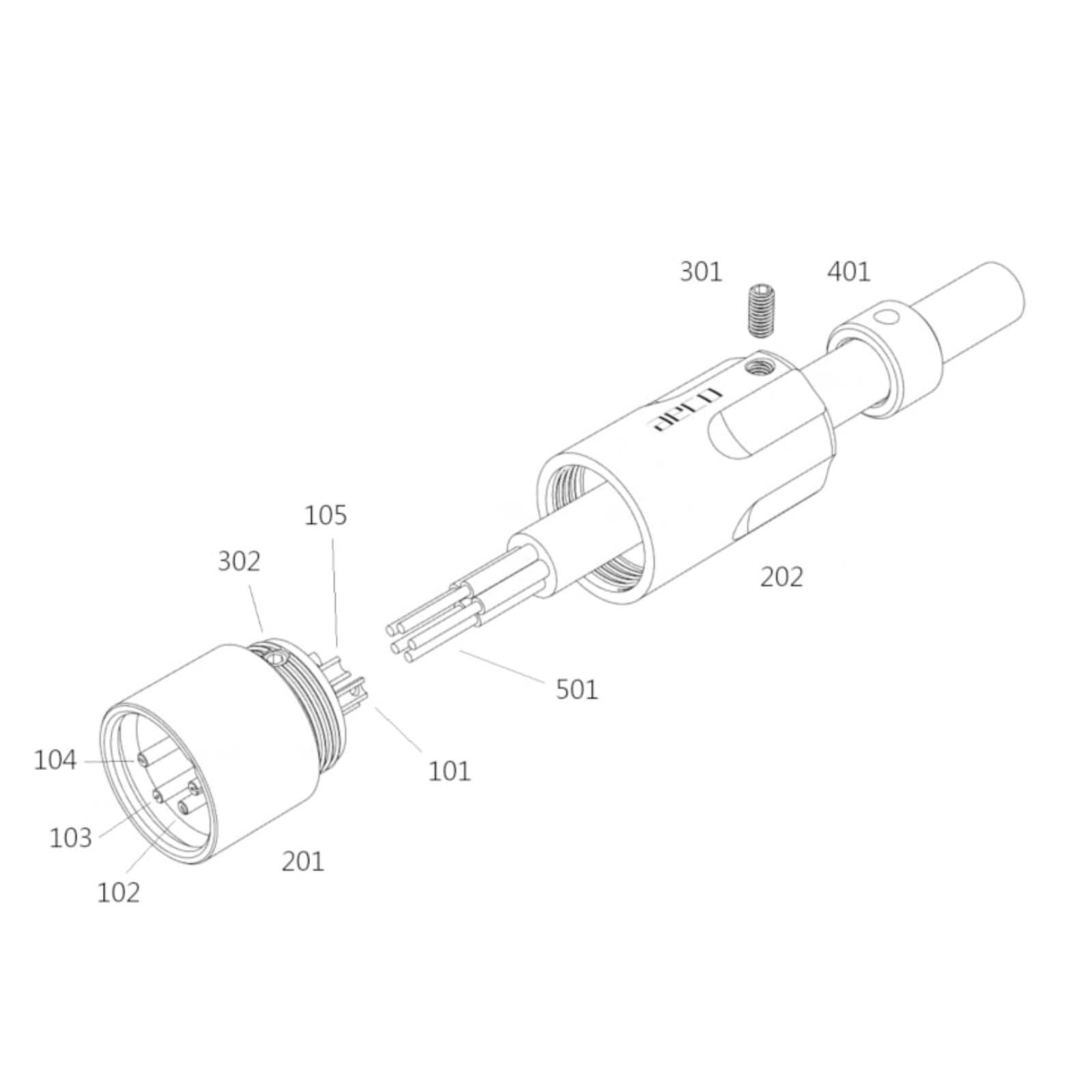

The Y spade interface with wave design that it with elasticity when the using within binding post,

Spade plug was half cross cutting shape and a brass ring with screw.

There have two methods for choose use, solder type or screw Locking the cable.

The shell and body isolated and assemble by insulator materials to complete the isolated function.

In order to avoid the insulation headlock melts during the solder process, the insulation headlock can be disassembled and after solder process it can be assemble back easily.

The conductor was used by high-purity copper (cooper: C1100 ) without nickel base.

Description

The Y spade interface with wave design that it can work well with binding post.The middle area of Y spade with through hole that it be used to fix the disassemble headlock with dovetail joint design.

After assembling the headlock that it can screw-in shell.

A ring and a screw were temporary locked so that is able to adjust into solder or keep lock directly based on your need.

POM sleeve is tighten with shell end together by screw

Note:

The Y spade body can’t overbend repeat , in order to avoid fracture of Y spade body.

The structure of wave are designed to withstand max 6 (lb/in) torque

Please take off the Nylon head lock for a while during soldering period.

Please control the soldering area as half-cutting area , or it will hard to assemble the nylon head lock back to body.

1. We recommend to peel off the cable jacket and appear conductor part about 6mm [201] .

2. This product is suitable for cable OD which is less than 6.3mm. Please remove the sleeve [171] if the cable OD is more than 4.3mm.

3. Please put the cable through the shell [161]4.1.1.Support the cable conductor diameter under 5.0mm or over AWG5 , please remove the ring [131] and the screws [141 / 142] then solder on the half cross cutting section

4.1.2. In order to avoid the melts during the solder process, the insulation headlock [121 / 122] can be disassembled temporarily.

4.1.3. Y spade body [111] put on the jig tool then start for the solder process.

4.1.4. Wait until the solder materials cool down.

4.1.5. Please noted that the disassemble headlock can split to bottom [122] and top [121] , and the bottom and top part with different dovetail joint design and directionality.

4.1.6 The headlock bottom part and top part can assemble on the Y spade body well through dovetail joint design

4.2 Support the cable conductor diameter under 3.5mm or over AWG8 , please put the ring [131] on banana body , then put the cable conductor into the ring , and use the screws [141 /142] tighten the ring and conductor.

5. Please lock the shell on headlock [121 / 122].

6. Please fix the cable and shell through screw [222 / 221].

ASP-1931G/R/S

Body: Copper (#C1100 / copper contains 99.9% at least )

ASP-1953

Body: Pure Silver (silver contains over 99.99%)Headlock: Glass fiber reinforced nylon (Red / White)

Ring: Brass alloy (#C3604)

Screw for conductor: Brass alloy (#C3604)

Shell: Stainless steel (SUS304)

Sleeve: POM

Screw for cable: Stainless steel (SUS304)

Finished:

ASP-1931R

Body: Rhodium plating (no nickel base)

Ring: Rhodium plating (no nickel base)

Screw for conductor: Rhodium plating (no nickel base)

Head lock: None

Shell: None

Sleeve: None

Screw for cable: None

Screw for conductor: None

Contact resistance < 0.4 mohm

(Pair testing with ABI-0601)

Dimension:

Biggest OD 13.8mm( Y spade interface)

Biggest OD 9.0 mm(shell )

Cable hole without sleeve 6.5mm

Cable hole with sleeve 4.5mm

Total Length 48.5mm

Packing:

Vacuum Bag(4Pcs/1Set)

Recommend soldering temperature:

Temperature Soldering Iron, please keep 400 °C within 3~5 second.

Temperature Soldering Iron, please keep 450 °C within 3~5 second.

In order to avoid the melts during the solder process, the insulation headlock can be disassembled temporarily.

Product production process comply with RoHS Directive.

This product is protected by the Taiwan Utility Model Patent No. I763038.

Related products

-

Gold Plated Tellurium Copper RCA Connectors Aeco ARP-4045 Set Of 4

0 out of 5Add to basket -

Sale!

Sale!

AECO ABC-1471 75 Ohm Gold Plated tellurium Copper BNC Connector (1 Pair)

0 out of 5Add to basket -

Sale!

ABI-0601R Pair Of Chassis Terminal Posts Rhodium plated Copper

0 out of 5Add to basket -

AX4-1611S AECO 4 Pin XLR Silver Plated Tellurium Copper Contacts

0 out of 5Add to basket

Reviews

There are no reviews yet.